Unlocking the Future: Logistics Demand Forecasting for Supply Chain Management

Inside this article:

In the rapidly evolving landscape of global commerce, one aspect has taken center stage: the ability to predict the future. Demand forecasting, especially within the realm of logistics, has emerged as a linchpin for operational success in modern businesses. By forecasting future demand with accuracy, companies are not only gaining a competitive edge, but they’re also optimizing their operations, cutting costs, and ultimately enhancing the overall customer experience.

This article will delve into the fascinating world of logistics demand forecasting, exploring its importance in supply chain management, how it works, and its integral role in industries such as warehousing and transportation services. We will differentiate between quantitative and qualitative forecasting methods, discuss the key factors influencing logistics demand forecasting, and delve into the exciting potential of AI and machine learning in this domain.

From there, we will touch on the various logistics demand forecasting software and tools available in the market, before concluding with best practices for implementing effective logistics demand forecasting in your business. By the end of this comprehensive guide, you’ll understand why logistics demand forecasting has been dubbed ’the next big thing in supply chain management’ and how mastering it can drive your business to new heights of success.

TL;DR

• Logistics Demand Forecasting is critical to Supply Chain Management. Accurate forecasting prevents overstock and stockouts, minimizes lead times, reduces costs, and improves customer service.

• In the broad logistics industry, key services such as warehousing, freight and transportation, and distribution channels depend on precise demand forecasting to enhance efficiency and reduce costs.

• Demand forecasting utilizes both Quantitative and Qualitative methods. Quantitative methods rely on historical data and trends, while qualitative methods draw insights from market research and expert opinions.

• The advent of technology has brought forth novel techniques like Deep Neural Networks (DNN) and complex Machine Learning (ML) models. These advanced methods can process large-scale data and identify complex patterns, resulting in highly accurate forecasts.

• Factors like data quality, seasonality, market trends, and external events significantly influence Logistics Demand Forecasting. Understanding these influences can improve the accuracy of forecasting and supply chain management.

• Both off-the-shelf commercial software solutions and custom-developed applications offer a wide range of tools for supply chain forecasting. The selection between these depends on a company’s specific requirements.

• nexocode AI experts, with extensive experience in the logistics sector, are ready to assist you in implementing AI solutions to improve your Logistics Demand Forecasting. Contact us today to start your journey toward an optimized and efficient supply chain management system.

The Importance of Logistics Demand Forecasting in Supply Chain Management

In an increasingly competitive global market, the ability to anticipate customer demand is a game-changer for any business. Logistics demand forecasting is critical for supply chain management, as it enables companies to predict customer demand, prevent stockouts and overstocks, minimize lead times, and improve customer service levels.

Accurate demand forecasting results in a plethora of benefits, such as optimizing production lead times, reducing costs, augmenting operational efficiencies, and enhancing the customer experience. Moreover, demand forecasting plays a pivotal role in implementing advanced logistics solutions such as dynamic pricing models, digital twins, just-in-time inventory management, and predictive maintenance. These solutions, fueled by accurate forecasting, can further optimize logistics operations, create efficient workflows, reduce waste, and ensure that businesses stay ahead in a highly competitive market.

Harness the full potential of AI for your business

Sign up for newsletterHowever, unforeseen occurrences can have a detrimental impact on the precision of active demand forecasting models. Variables such as seasonality, supply chain trends, the economy, and global events can cause spikes or sluggish sales, which can affect inventory control. To mitigate these challenges, an accurate demand forecast is essential.

To overcome these challenges, it is advised to implement data collection and preparation, real-time data processing, continuous monitoring and improvement, and collaboration and communication for effective logistics demand forecasting.

Unveiling Logistics Demand Forecasting - Demand in Logistics, Warehousing, and Transportation Services

The sphere of logistics is a complex web of interdependent sectors, each reliant on effective demand forecasting to ensure efficient operations. To truly comprehend the breadth of logistics demand forecasting, it’s important to understand its implications across various service areas within the logistics domain, such as freight transportation, warehousing, distribution services, and reverse logistics.

Freight Transportation

Freight transportation, whether it’s by air, sea, rail, or road, forms the very backbone of global commerce. An accurate demand forecast in this sector can provide insights into shipping volumes and frequencies, which in turn facilitates strategic planning and resource allocation. Better demand forecasts allow carriers to optimize their routes, minimize fuel consumption, and reduce idle time, leading to more cost-effective operations and a lesser environmental footprint.

Warehousing

The role of warehousing extends beyond just storage. It’s about ensuring the right products are available at the right time. Effective demand forecasting aids in proper space utilization, labor management, and inventory control. By forecasting demand, warehouse managers can efficiently plan for peak periods, ensuring adequate staffing and inventory levels to meet the demand, thereby reducing stockouts or overstock situations.

Distribution Services

At the heart of an efficient distribution network lies effective demand forecasting. By predicting the demand for goods, distributors can better manage their stock levels, ensuring the right products are delivered to the right places at the right time. Accurate demand forecasting helps prevent stock shortages or surpluses at distribution centers, fostering smooth operations and improved customer satisfaction.

Reverse Logistics

Reverse logistics, dealing with returned products and their reintegration or disposal, is another area where demand forecasting plays a crucial role. Predicting the volume and timing of returns can help companies to plan return processes more efficiently. This allows for cost-effective resource allocation for product repair, restocking, recycling, or disposal, thus enhancing the sustainability of operations.

In each of these sectors, demand forecasting is not just about operational efficiency; it’s also a key element of supply chain management. By anticipating future demand, companies can streamline their supply chains, leading to reduced lead times, minimized costs, improved service levels, and a more robust bottom line. As such, mastering logistics demand forecasting is a vital step toward a more resilient, responsive, and sustainable supply chain.

To achieve forecasting success in logistics, warehousing, and transportation services, businesses employ a combination of qualitative and quantitative forecasting methods.

By leveraging these supply chain forecasting methods, businesses can reap the benefits of cost savings, resource conservation, optimized operations, and lower operating costs.

Quantitative vs. Qualitative Forecasting Methods

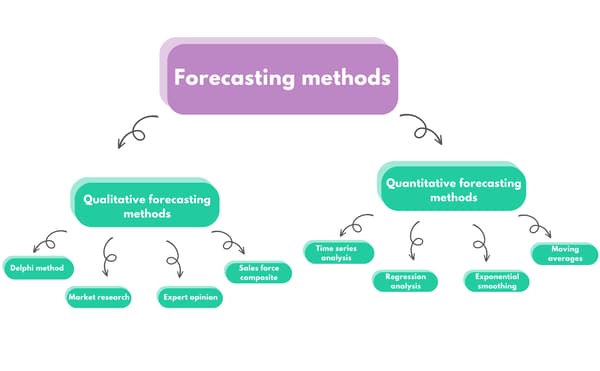

Forecasting methods can be broadly classified into two categories: quantitative and qualitative. Quantitative methods rely on historical data and trends to generate predictions about future outcomes, while qualitative methods depend on market research and other industry analyses to make estimates when data is scarce. Time series analysis, causal models, and regression analysis are among the most commonly used quantitative forecasting methods.

On the other hand, market research, expert opinion, sales force composite, Delphi method, and the econometric method are some of the most widely used qualitative forecasting methods.

Quantitative Forecasting Methods

Quantitative forecasting methods employ mathematical models and historical data to generate projections regarding future demand. Traditional methods include moving average forecasting, econometric demand forecasting, time-series analysis, trend projection, and Multiple Aggregation Prediction Algorithm (MAPA), which each offer unique advantages and limitations.

To enhance the accuracy of quantitative forecasting methods, businesses can incorporate additional future plans, such as marketing events, and assumptions or growth modeling, for accurate demand planning. Furthermore, it is essential to take into account historical anomalies, such as abrupt increases in demand or decreases in sales due to external factors, when utilizing trend projection methods. By doing so, companies can achieve a more reliable demand forecast.

However, with the advent of advanced technology, more complex and sophisticated quantitative forecasting techniques have been developed, such as Deep Neural Networks (DNN) and complex Machine Learning (ML) models.

Deep Neural Networks

Deep Neural Networks are a subset of AI that mimics the way the human brain works, providing superior capabilities for identifying patterns and making predictions from large amounts of data. In the context of demand forecasting, DNNs can digest and process a vast array of data points, uncovering intricate correlations and patterns that would otherwise be overlooked. This deep learning technique can forecast demand with a higher degree of accuracy than traditional methods, particularly in scenarios with large-scale data sets or complex, nonlinear relationships between variables.

Complex Machine Learning Models

Complex Machine Learning models have risen to prominence as powerful tools in demand forecasting. Techniques such as Gradient Boosting, Random Forests, and Support Vector Machines have proven to be highly effective in predicting future demand.

These models can process and learn from large datasets, identify complex patterns, and make highly accurate forecasts. They are especially useful in cases where traditional forecasting methods may struggle due to the high dimensionality and nonlinearity or when dealing with many influencing factors that interact in complex ways.

One noteworthy advantage of complex ML models in forecasting is their ability to accommodate new types of data, such as social media activity or weather forecasts. They can be trained to analyze unstructured data and incorporate it into the forecasting model, adding another layer of sophistication and accuracy to demand forecasting.

While these novel techniques come with their own set of challenges, such as the need for significant computational power and expertise in model tuning and interpretation, their potential benefits are substantial. By incorporating these advanced methods into their forecasting strategies, companies can navigate complex market dynamics and stay one step ahead of demand, boosting operational efficiency and business success.

Qualitative Forecasting Methods

Qualitative forecasting methods, on the other hand, rely on subjective or non-mathematical data to predict future demand, especially when historical data is unavailable or difficult to obtain. Some common qualitative forecasting methods include historical analogy forecasting, panel consensus, Delphi method, and sales force composition method.

While qualitative methods can provide useful insights, they are generally less precise than quantitative methods, which are based on past information and mathematical models. However, qualitative methods are frequently utilized in conjunction with quantitative methods to generate more precise forecasts.

Key Factors Influencing Logistics Demand Forecasting

Logistics demand forecasting is influenced by a variety of factors, such as data quality, seasonality, market trends, and external events. Understanding these factors and their impact on supply chain forecasting is crucial for businesses to make informed decisions regarding inventory levels, pricing, and other aspects of supply chain management.

Let’s delve deeper into each of these factors and explore how they can affect the accuracy and effectiveness of logistics demand forecasting.

Data Quality

Data quality is an evaluation of how well a dataset adheres to criteria such as accuracy, completeness, validity, consistency, uniqueness, timeliness, and fitness for purpose. High-quality data is essential for accurate logistics demand forecasting, as it forms the foundation of any data analysis process.

Maintaining data quality can be challenging due to issues such as data integrity, security, and privacy. However, by implementing robust data governance initiatives, businesses can ensure that their data is precise, reliable, and of high quality.

Seasonality

Seasonality refers to the periodic fluctuations of demand or supply of a product or service over a given period, making it difficult for businesses to accurately forecast inventory levels. Seasonality can be observed in various industries, such as retail sales, which typically peak during the Christmas season and decline afterward.

To overcome the challenges associated with seasonality, businesses can employ forecasting methods specifically designed to address seasonality.

Market Trends

Market trends play a vital role in supply chain management, as they offer insight into the present and prospective state of the market. By understanding market trends and their impact on demand forecasting, businesses can make informed decisions regarding inventory levels, pricing, and other aspects of supply chain management.

To successfully forecast market trends, it is essential to gather and organize data, process data in a timely manner, consistently assess and improve predictions, and work together and exchange information with relevant parties.

External Events

External events, such as natural disasters, geopolitical developments, or changes in regulations, can have a significant impact on supply chain management, leading to disruptions and affecting inventory control. By being cognizant of external events and strategizing for them, businesses can reduce their influence on the supply chain and maintain efficient operations.

Examples of external events include natural disasters like floods or earthquakes, trade disputes, regulatory changes such as tariffs, and supply chain disruptions like strikes or supply shortages.

Implementing AI and Machine Learning in Logistics Demand Forecasting

The advancements in artificial intelligence (AI) and machine learning have opened up new possibilities for logistics demand forecasting. By harnessing the power of these cutting-edge technologies, businesses can significantly improve their forecasting accuracy and efficiency.

Let’s explore the benefits of implementing AI and machine learning in logistics demand forecasting and the steps needed to successfully integrate these technologies into the forecasting process.

Benefits of AI and Machine Learning

AI and machine learning offer a multitude of benefits when it comes to logistics demand forecasting. These technologies can analyze large volumes of data and identify patterns that may not be easily detected by humans, resulting in more accurate and efficient forecasts.

Moreover, AI-enabled demand forecasting can consider various factors such as historical sales data, current trends, and social media chatter to further optimize the forecasting process. In short, embracing AI and machine learning can be a game-changer for businesses seeking to improve their logistics demand forecasting capabilities.

Steps to Implement AI and Machine Learning

Implementing AI and machine learning for logistics demand forecasting requires a strategic approach. The process begins with data collection and preprocessing, which involves gathering data from various sources, cleaning and formatting it, and transforming it into a format suitable for use by the machine learning model.

Next, businesses need to select the optimal machine learning model for their specific needs, train the model on the data, and adjust the model parameters to maximize performance. Once the model is trained, it can be deployed in a production setting, where its performance can be monitored and adjusted as needed.

Continuous monitoring and improvement are essential for ensuring the ongoing success of AI-enabled logistics demand forecasting.

Logistics Demand Forecasting Software and Tools

A wide array of logistics demand forecasting software and tools are available to cater to the unique needs of businesses. These solutions range from commercial off-the-shelf products to custom-developed applications tailored to specific requirements.

Let’s discuss the various options and their suitability for different businesses.

Commercial Software Solutions

Commercial software solutions for logistics demand forecasting, such as SAP Integrated Business Planning, IBM Planning Analytics, Blue Ridge Global, Oracle, Fishbowl, and Salesforce for Transportation & Logistics, offer a range of features and benefits. These solutions leverage machine learning, demand modeling, and predictive analytics to forecast product demand, making them ideal for businesses seeking a ready-to-use solution for their forecasting needs.

These solutions provide a comprehensive suite of features, such as automated demand forecasting, inventory optimization, and supply chain analytics. They also offer a range of benefits, including improved accuracy, faster response times, and cost savings. With these solutions, businesses can make more informed decisions and better manage their supply chain operations.

Custom Development

Custom development of logistics demand forecasting software involves creating a tailored solution that meets a company’s specific requirements and specifications. This can range from building a forecasting model from scratch to adapting an existing one to meet unique needs.

Businesses can opt to develop their own software or engage a software development company to create a custom solution, depending on their resources and expertise. Custom development offers greater flexibility and customization, allowing businesses to create a solution that is perfectly suited to their unique needs and challenges.

Best Practices for Effective Logistics Demand Forecasting

To unlock the full potential of logistics demand forecasting, it is essential to follow best practices that ensure the accuracy and effectiveness of the forecasting process. These practices include data collection and preparation, real-time data processing, continuous monitoring and improvement, and collaboration and communication.

Let’s delve deeper into each of these practices and explore how they can contribute to successful logistics demand forecasting.

Data Collection and Preparation

Data collection and preparation are the foundation of any data analysis process, and their importance in logistics demand forecasting cannot be overstated. Ensuring the accuracy of data collection, selecting an appropriate forecasting technique, and taking expert opinion into consideration are all crucial steps in the data collection and preparation process.

By adhering to these best practices, businesses can minimize the risk of errors and enhance the accuracy of their logistics demand forecasts.

Real-Time Data Processing

Real-time data processing is a powerful tool for logistics demand forecasting, as it enables businesses to make informed decisions quickly and efficiently. Identifying objectives, scope, and variables, analyzing the relationship between sales forecasts and sales promotion plans, and processing data in a timely manner are all essential steps in the real-time data processing process.

By following these best practices, businesses can ensure that their logistics demand forecasts are accurate, timely, and actionable.

Continuous Monitoring and Improvement

Continuous monitoring and improvement are vital for maintaining the accuracy and effectiveness of logistics demand forecasts over time. By regularly evaluating the performance of their supply chain and taking corrective action to optimize it, businesses can ensure that their logistics demand forecasting process remains on track and delivers the desired results.

This proactive approach to monitoring and improvement can lead to increased efficiency, enhanced customer service, and reduced costs.

Collaboration and Communication

Effective collaboration and communication are crucial for the success of any logistics demand forecasting process. By involving domain experts in the forecasting process, businesses can gain valuable insights into customer behavior and market trends, which can help improve the accuracy of their forecasts.

Additionally, adopting a collaborative approach and exchanging information with relevant parties can ensure that the forecasting process is based on reliable data and insights from multiple sources. By embracing these best practices, businesses can enhance the accuracy and effectiveness of their logistics demand forecasts.

Embracing the Power of Logistics Demand Forecasting

Embracing the power of logistics demand forecasting can help businesses optimize their operations, increase efficiency, and stay ahead of the competition. By following the best practices discussed in this blog post, businesses can harness the full potential of logistics demand forecasting and make data-driven decisions that drive growth and success.

From understanding the importance of logistics demand forecasting in supply chain management to implementing cutting-edge AI and machine learning technologies, the opportunities for improvement are endless. Are you ready to unlock the future and take your business to new heights?

Don’t navigate the complex world of logistics demand forecasting alone. Contact the AI experts at nexocode, who bring extensive experience in the logistics sector to the table. Our team can guide you in implementing the most effective AI solutions for your business, helping you leverage the power of advanced technology for accurate and efficient demand forecasting. Reach out to nexocode today and embark on your journey towards a smarter, data-driven future.

Frequently Asked Questions

Logistics demand forecasting is the process of estimating future demand for products or services within the logistics sector. It involves the use of statistical tools and analytics to predict future trends based on historical data, current market conditions, and potential future events.

-

Why is Logistics Demand Forecasting Important in Supply Chain Management?

Logistics demand forecasting plays a crucial role in supply chain management. It enables companies to predict customer demand, prevent stockouts and overstocks, minimize lead times, and improve customer service levels. Furthermore, accurate demand forecasting also feeds into other beneficial solutions such as dynamic pricing models, digital twins, and capacity planning.

-

How Does AI and Machine Learning Improve Logistics Demand Forecasting?

AI and machine learning technologies improve logistics demand forecasting by enabling the analysis of vast amounts of data at an unprecedented scale and speed. They can identify complex patterns and trends that may not be easily detected by humans, resulting in more accurate and efficient forecasts. Moreover, AI can consider various factors such as historical sales data, current trends, and social media chatter to optimize the forecasting process.

-

What Are Some of the Key Factors Influencing Logistics Demand Forecasting?

Key factors influencing logistics demand forecasting include data quality, seasonality, market trends, and external events. High-quality data forms the foundation of accurate forecasting, while understanding the impact of seasonality and market trends can enhance the accuracy of predictions. External events, such as natural disasters or changes in regulations, also need to be considered as they can significantly impact supply chain operations.

-

What Are Some Best Practices for Effective Logistics Demand Forecasting?

Best practices for effective logistics demand forecasting include ensuring accurate data collection and preparation, utilizing real-time data processing, continuous monitoring and improvement of forecasting models, and fostering collaboration and communication within the organization.

-

How Can nexocode's AI Experts Help Improve My Logistics Demand Forecasting?

nexocode's AI experts have extensive experience in the logistics sector and can guide you in implementing the most effective AI solutions for your business. By leveraging the power of advanced technologies, nexocode can help your business achieve more accurate and efficient demand forecasting, enabling you to optimize your operations, reduce costs, and enhance customer satisfaction.