Software Services for the Logistics Industry

There are a variety of artificial intelligence solutions that can be tailored to different industry needs. To make sure you get the most out of your project, our AI Experts will select the best approach for the specific needs of your business to build resilience and a competitive edge. Nexocode provides a range of services to help logistics companies and supply chain organizations. These include:

Logistics Operations Optimization - Nexocode builds a strategy based on a deep understanding of your business and available data (orders, invoices, SKUs, traffic, or other transportation data) to help you optimize your operations. We can help you identify opportunities within a given market by creating ML models for optimization, insights, and cognitive automation.

Predictive Analytics - Our AI Experts will help you become proactive and predictive, freeing time to focus on what matters most. Advanced machine learning algorithms to a data set can produce accurate predictions for future events and trends (demand forecasting, predictive maintenance, predictive fleet management).

Natural Language Processing - We create NLP and NLG systems to convert text into actionable insights. These applications can be used to extract a meaningful summary from a large amount of content or find the most relevant information in a set.

Image Analysis and Recognition - Our solutions can extract insights from various images, including those from warehouses and roadways. You may want to use computer vision solutions for quality assurance, cognitive automation, or autonomous actions.

Optimized Routing and Scheduling - Nexocode's team has vast experience in developing logistics solutions that aim to optimize routes and schedules of deliveries to limit fuel consumption, reduce emissions, provide cost-efficiency and timely deliveries.

Dynamic Pricing Models - We offer custom development of AI-based dynamic pricing models that can be implemented to various logistics services (freight forwarding, trucking, shipping) to maximize revenue and profits.

Do you want to talk

about your idea?

Our Case Studies

nexocode is a company that offers AI development services dedicated to the logistics and supply chain industry and has a broad portfolio of successful projects within these fields. Our AI applications can bring operational success to various logistics and SCM fields. For our clients, we develop solutions that improve efficiency, optimize processes, reduce costs, and increase productivity. Check our portfolio of successful implementations below.

Artificial Intelligence in Logistics, Transportation, Shipping and Supply Chain Sectors

Technology impacts every aspect of our lives and plays a strategic role in the logistics industry. Applications of AI within the sector are a logical step forward. Artificial intelligence can dramatically improve a business's performance, whether it is a small or a large enterprise. It will become a game-changer for the entire industry.

Within the transportation, shipping, logistics & supply chain industries, AI technology stands out as a solution that can help businesses improve productivity by automating tasks, streamlining processes, increasing resource allocation, and providing better data management through actionable insights.

Given that there are several different AI applications available on the market for logistics companies today, it is essential to understand how each solution works to make a more informed choice about which one is right for a particular business' needs. Below you can find a brief introduction to AI applications for the logistics industry.

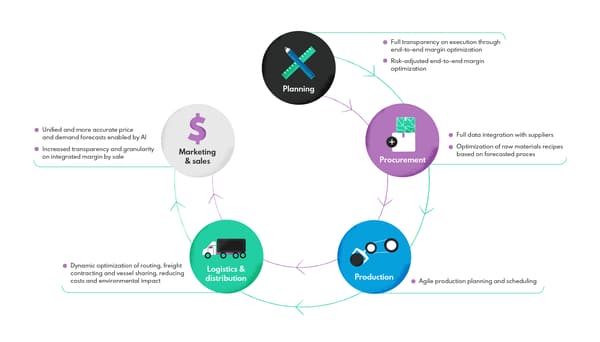

Benefits of AI on every step of the supply chain operations flow

Smart Freight Matching

Shippers use various business networks to find the best carrier for their goods. However, most matching is carried out manually by posting and searching through offers within the network. The ever-growing number of offers and needs makes finding a suitable match within a budget challenging. Artificial intelligence can be applied for a more intelligent freight matching with a carrier. Machine learning algorithms identify a carrier for a particular load based on available information - the origin, destination, commodity type, weight, size dimensions. Thanks to that, the model can select a shipper with a carrier that offers service at a time, place, and price suitable for both parties.

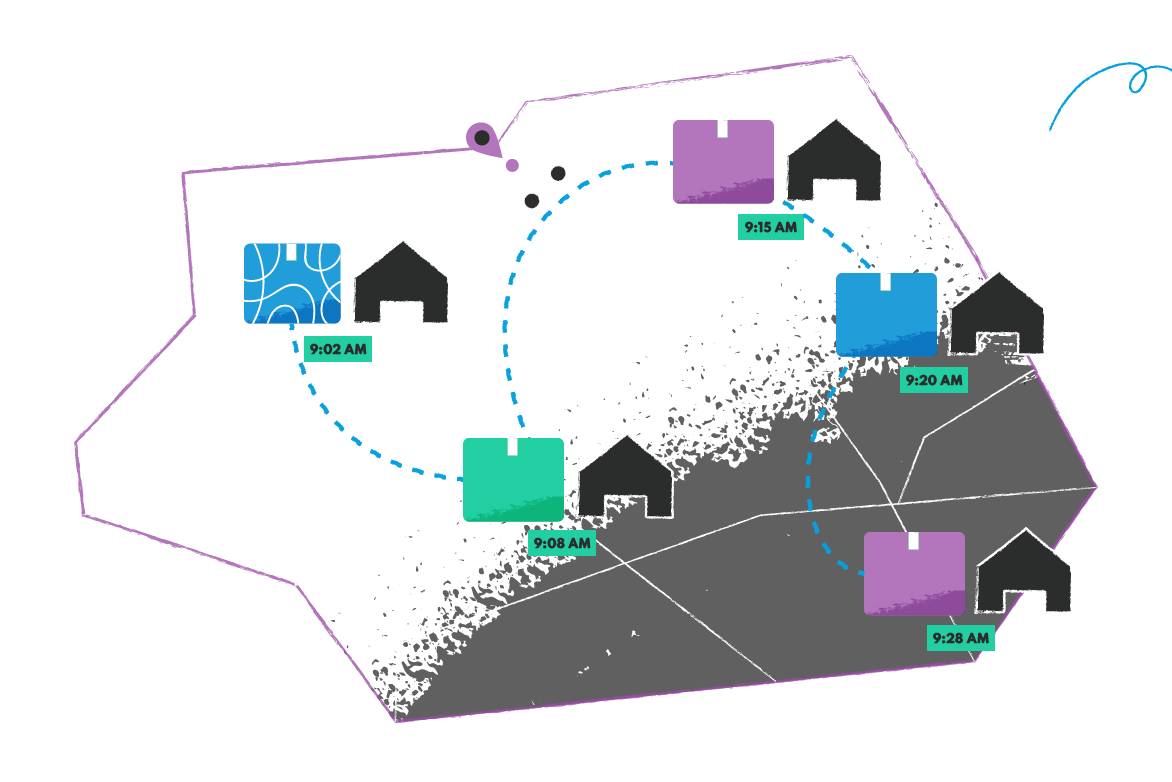

Efficient and Sustainable Last-mile Logistics

Optimization is a key element of any logistics network. It helps to deliver goods in the most efficient way, which will result in reduced costs and improved service quality for customers. For example, a company that has a warehouse in two different cities may need to decide between sending a driver from one city to another without any return trips, taking a load directly from the production line in the other town, or even solve a challenge of combining both routes into a single one.

A great example of a logistics task where AI can be used is a routing problem, which involves finding an optimal path throughout a given network that meets required delivery times while following specific rules or restrictions.

Routing optimization algorithms generate a set of solutions (routes) that define the best possible delivery path, considering various parameters like loading times, freight, restrictions on the load or carrier capacities. Route optimization helps choose an optimal way for each vehicle depending on its capabilities, traffic conditions, and the availability required throughout the journey. The model considers all possible variables before coming up with an answer, thanks to historical data that already have been used by thousands of vehicles daily.

Efficient route optimization enables lowering transportation costs through minimal fuel usage, optimized schedules, and efficient allocation of drivers and trucks.

Efficient and Sustainable Last-mile Logistics

The e-commerce industry is a fast-growing market in the twenty-first century. It has a massive impact on the entire logistics sector. Online shops or e-commerce platforms greatly need fast and cost-effective goods delivery to their customers. What is blocking them? It is mainly the challenge of efficient last-mile logistics. Last-mile delivery is a complex choreography of all the participants involved in a supply chain - a fleet operator, a courier, a freelancer who owns a car, or a scooter. The last mile delivery constitutes a good part of the final price due to its high costs, mainly affected by fuel expenses, driver wages, and vehicle wear. AI can help reduce all these factors thanks to many solutions.

AI has a lot to offer for other significant problems and cost drivers in last-mile logistics like failed deliveries, returns, and deliveries complaints. Solutions for last-mile deliveries operate within route and schedule optimization, fleet management, and predictive analytics that enable intelligent planning.

Optimizing Fuel Consumption and Emissions Reduction

Autonomous vehicles can bring a sizable reduction in costs due to a high volume of delivery. It is a crucial factor for last-mile deliveries where a volume is lower and a cost per unit is higher compared with a traditional supply chain. The last mile logistics market has a lot to gain from the use of autonomous delivery solutions. Driverless technology can be used both for shorter range or local distribution which involves a small number of stops, as well as long-distance distribution.

Self-driving cars or trucks are a solution that can significantly reduce the number of accidents with no or a low number of casualties. They also can be used to carry dangerous materials like flammable cargo which requires a special permit and a higher level of safety before being allowed on public roads without a human driver.

Autonomous Ships and Port Operations

Just like for land transportation, autonomous vessels and port machinery are a big area of interest for a number of large shipping companies. They are a key element to improve productivity, efficiency, and safety in shipping and port operations. AI may assist a ship captain with docking a vessel at the pier, monitoring risks of collision or grounding, handling cargo operations that require a high level of precision, and much more.

AI-enabled devices can also be used to reduce costs and save time during container loading and unloading processes. A significant part of activities at a terminal is automated with the use of various types of equipment like cranes or reach stackers that can easily be operated by an AI system as well as machine vision technology such as Automatic Guided Vehicles (AGVs).

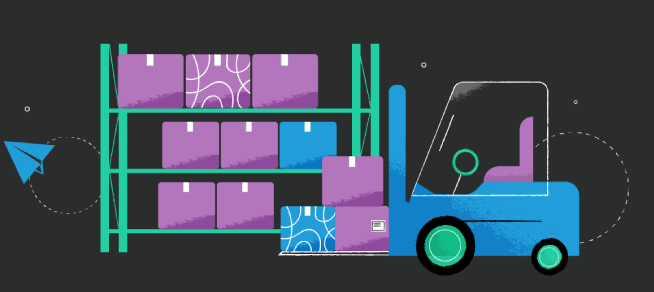

Automated Warehouses

Another example of an excellent benefit for the logistics sector is a fully automated warehouse. Logistics companies worldwide are facing a lot of challenges in warehouse management. It is a costly business, and a simple mistake can be a reason for a considerable loss. In addition to that, it is becoming increasingly difficult to find a skilled workforce that will support warehouse operations, especially with growing demand and the seasonal aspect of the workforce needs.

That is why more and more logistics managers decide to move towards warehouse automation by using robotic devices which operate with no human intervention. The most common use cases include automatic storage and retrieval systems (AS/RS), autonomous mobile robots, order picking machines guided by laser or RFID technology. AI systems can be used to navigate a warehouse space, identify a needed good in an inventory, pick it up and place it in a storage location or a delivery vehicle with no human intervention. A task like this currently requires a person to be present, which makes it risky and time-consuming.

AI-enabled warehousing solutions are expected to help companies decrease their expenses related to activities performed by human specialists working in warehouses, including employees' salaries, physical risks due to human error, fatigue resulting from long periods of standing on picking positions or operating a forklift, or other types of equipment that can be automated.

Inventory Management

A solution that many companies are looking forward to getting is a machine learning-based inventory management system. It can increase a volume of a product a warehouse can hold by accurately predicting demand for specific products and trigger a restocking process before a good becomes obsolete.

AI-powered warehouse management may greatly benefit a company by several key factors such as a quick response to a customer by providing a required good and fast reordering process. This is a critical success factor for a supply chain management sector because an out-of-stock situation can cause a loss of customers and revenues. An intelligent inventory system could also forecast stock levels or even identify products that require a replacement or an update. A data feed from other business units within the same company may help with this process, so it would not only provide information about sold goods but also unnecessary stocks, which can, later on, be used as a source for new items throughout the entire supply chain performance.

Integrating AI technology in warehouses can also help in quality control by supporting various operations with an automated visual inspection, a quality check for many products in a warehouse. Machine vision can also be used to monitor a product's condition in a way that cannot be done manually.

Dynamic Pricing Models

Prices of logistics and transportation services are fluid, and accurate price setting is a must whether you're a service provider or a buyer. The prices for a given route or a service depend on a number of factors such as a level of demand, time, weather conditions, and even geopolitical issues.

AI-powered solutions can help not only with adjusting prices automatically but also provide insights about reasons behind them, like demand changes, delays, disruptions, and overcapacity, which will assist managers with making decisions about future business plans and price settings.

Dynamic pricing of logistics services is an excellent example of a domain where AI can be a game-changer. A company that wants to implement a dynamic pricing solution needs data about performance, both historical and recent. It should also consider seasonal variations or current demand for a good and competitors' prices to create demand forecasting models. All these factors combined should help an intelligent system improve its price estimates to provide a customer with the best offer for their order. If artificial intelligence models are used, it may even find patterns within this data, thanks to which it can constantly adjust its recommendations depending on specific preferences of individual customers, like seasonality or location.

Planning Distribution

Planning a distribution of a large number of goods between several warehouses is a time-consuming task handled by many distribution specialists and fleet managers supported by complex IT platforms. The distribution process can be improved with the help of AI, which will allow a company to get insights about a demand for a given product, desired schedules, possible routing, and fleet, analyze data and plan distribution more precisely and in a shorter amount of time.

It is one of the most complex tasks in supply chain management because it requires multiple resources, constraints, and other factors to be considered. A classic optimization problem for this domain would involve defining needs and schedules for freight, fleet, people, demand, and other multidimensional factors.

AI models used for this problem operate within predictive analytics and prescriptive scheduling supported by other, more-targeted solutions. An algorithm for this type of process should be able to prepare a plan taking all possible interactions into account. It means a model should consider not only a sequence of a planned activity but also a way they are connected together within the supply chains. Technology can help with this process by providing an AI solution that can learn from historical facts and make predictions about future events. ML models can do a great job finding patterns within a massive amount of data that may be used as actionable insights or statistics to run simulations for various scenarios. They can be optimized for multiple targets like cost-effectiveness, timely deliveries, warehouse space reduction, or a mix of all, depending on the needs of particular business specifics.

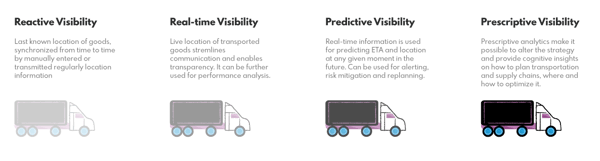

From reactive and real-time visibility of the fleet, cargo details, schedules, etc., to predictive and prescriptive modeling for fleet and route optimization.

The results obtained from this analysis build supply chain resilience. AI technology assists managers with making business plans and calculating costs to develop a strategy that would work best in accordance with their goals. It might also enable them to adjust the entire supply chain by eliminating unnecessary inventory or improving processes within specific areas like warehousing or scheduling, limiting operational costs. With a specialized predictive planning system, a logistics company can optimize such decisions as several different factors may be taken into account, like costs, delays, safety, traffic, or weather conditions.

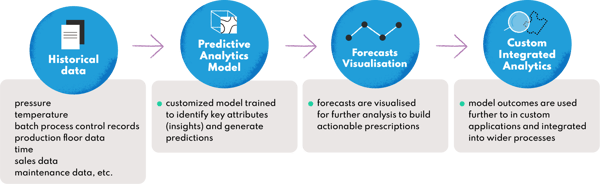

Predictive modeling enables production and distribution optimization through better throughput, quality, safety, and yield improvements. The end-to-end custom implementation of a solution that interprets data provides visualization and enables custom automated actions to streamline logistics and supply chain networks is essential to take SCM to the next level.

Predictive modeling enables production and distribution optimization through better throughput, quality, safety, and yield improvements. The end-to-end custom implementation of a solution that interprets data provides visualization and enables custom automated actions to streamline logistics and supply chain networks is essential to take SCM to the next level.

Securing Supply Chains

AI can be used to provide logistics security services that monitor a complex system of users and devices for suspicious activities, unusual events, or anomalies in activity patterns. This is achieved through a series of layered algorithms designed for anomaly detection and can alert about an event even when the data show no obvious indication for concern. This approach enables us to deal with potential threats before they become actual threats.

Planning shipment of containers - Predictive Scheduling

Machine learning models provide a great way of finding patterns within a large amount of data and help optimize the decision-making process by simulating several scenarios. Predictive scheduling is a good example of a process that can benefit from machine learning. Planning a shipment of containers is one of the most complex logistics tasks that require a large number of multidimensional factors to be taken into consideration.

Predictive scheduling in maritime enables planning shipments for cargo that are built upon a set of known factors and prior experiences which cover a larger group of shipments. Data collected from a wider range of resources can provide a more comprehensive context to work with and will allow a model to make well-informed decisions about future events. Machine learning models can help with this task by using historical data about shipments, ordered and predicted loads (supported by demand forecasting), or other types of recent events which may be related to the current activity. Predictive scheduling models aim to find patterns within data, calculate probabilities, and make reliable estimates about future events.

Predictive scheduling is a technique used in several shipment applications that provides a better quality of service to customers by making a plan for an optimal delivery route, schedule, and containers allocation. This information will be helpful in preparing a schedule that maximizes efficiency and time-effectiveness, even taking recent events into account like delays at the docs or weather conditions.

Managing Vessel Capacity and Organizing Containers Positioning

Containers vary in size, weight, and intended destination, and cargo ships move hundreds of containers at once. These differences make the order of placement crucial to improving productivity. Some of these are incredibly urgent items with a specified time limit in which they must be moved to a new port. On the other hand, others have longer transport durations and are not considered essential or rapid-transport goods.

On the subject of container shipping, there are several things to consider. The ability to determine and distinguish containers and products according to when they will be delivered is critical. This can ensure that goods with a crucial need receive priority over other items and are loaded on the vessel as soon as possible, simplifying trade flows between ports.

Furthermore, by adequately distributing products among the hundreds of vessels that pass through a port, terminal traffic may be decreased, optimizing schedules and reducing shipping costs. Managing vessel capacity and container positioning is an integral part of the shipping process that AI capabilities can optimize.

Using a number of metrics, AI analysis can determine the best place to load a container on a vessel. The task involves a lot of variables that are different for every ship, its size, location, time constraints, and other factors, which means that a solution will have to be specialized according to specific parameters. Machine learning models can plan container positioning by analyzing a number of factors about a shipment, a vessel, or ports on the route. An innovative solution to this problem is a system capable of understanding the whole picture by considering a bigger range of variables related to a specific ship at a given time, including weather conditions, time constraints, or even political events that may impact the whole picture of the voyage.

Predictive Maintenance

Another business application for machine learning is a predictive maintenance system that analyzes several factors like a component's history, the environment in which it operates, or variables within a part itself to determine when a piece of machinery will require service. Predictive maintenance solutions can be applied in all stages of supply chain operations, wherever there is machinery involved (ships, trucks, warehouse machines, port machinery, just to name a few examples). An efficient predictive supervision model can support users by identifying the cause of an issue and its severity. This information helps prioritize repairs, thus optimizing time management and reducing costs related to unplanned downtime.

For example, many algorithms consider previous levels of wear at similar points in time, environmental factors that may lead to problems, how long parts have been in use, etc., to predict future performance. A machine learning model can help a company plan a schedule for regular machine service relevant to a manufacturer's recommendation or a service technician's schedule.

When a machine is in a critical condition, and a delay may lead to a breakdown, a prediction model can assign a task of performing emergency maintenance and replacing a broken part before it fails completely. This action allows for the immediate continuation of productive activities without any downtime.

Predictive analytics solutions for parts/machinery wear out that support this type of decision-making could help minimize machinery downtimes related to unplanned repairs by reducing the need to make such decisions manually by operators themselves and limiting accidents levels. Using these systems as a tool for predictive maintenance, companies can reduce equipment downtime and thus increase productivity across entire supply chains operations.

Demand Forecasting

Predictive analytics solutions can also be valuable for demand prediction and global supply chain planning. For companies operating in a competitive environment, such a model can help minimize risks related to a lack of inventory by producing a highly accurate demand prediction.

As a result, a firm can better prepare itself to meet an increase in demand and avoid shortages, especially when the goods under consideration are slow-moving and far from a warehouse. Having access to reliable data about future trends and events gives organizations time to make necessary changes, including acquiring more supplies or expanding production capacity if required.

With this information, businesses can optimize their supply chains processes with improved accuracy, which can significantly lower operational costs due to more efficient operations.

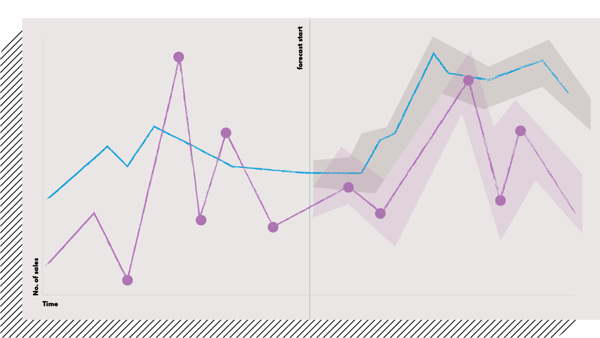

Predicting sales based on past patterns in demand to optimize the production and transportation processes.

Some predictive models learn almost instantly on a massive data-set and can produce forecasts in real-time. While a micro-forecast is a short-term prediction that helps a company adjust its inventory for a specified period; it means that the model would be able to issue warnings about potential supply chain problems with high accuracy.

Demand forecasting is essential when it comes to planning capacity and schedules and evaluating optimal pricing strategies. By taking a market forecast into account, a company can define the optimal price that will cover costs of service and ensure a profit margin and attract a maximum number of customers, thus maximizing sales figures.

Predictive analytics solutions can also be applied to inventory management processes. They leverage a considerable amount of historical data about customer behavior to optimize lead time through proper merchandising (e.g., schedule replenishment according to real-time supply and demand). Thus, a company can deliver goods in time without the risk of potential material shortages or a surplus that may lead to additional costs.

The data about historical demand patterns can be used to forecast future demand for a product enabling a business to fulfill orders faster, improve its supply chain optimization processes and increase customer satisfaction which helps attract new clients thus improving the bottom line by generating more revenue.

Streamlining Backoffice Operations with NLP

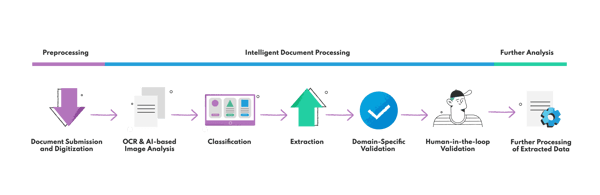

How can AI extract data from any document with intelligent document processing?

Solution providers in the logistics industry are also integrating Natural Language Processing (NLP) capabilities into their offerings to leverage a considerable amount of document, written communication, and unstructured text data available in a particular company. Such a system can rapidly extract the necessary information for a specific business to enhance its back-office automation.

Processing invoices, bills of ladings, customs declarations, purchase orders, packing lists, and all other documents a logistics company needs to handle daily is a very time-consuming and labor-intensive process. As a result, a lot of money is wasted through manual human work and many mistakes made in documents processing which could have been avoided if the data was automatically extracted from a document by a computer.

Depending on a business' needs, NLP can solve a specific problem or provide a complete technology solution for automating an entire back-office function using natural language processing and custom software development. NLP solutions can be applied for automated reading and extracting specific data from documents (natural language understanding - NLU) or for generating new documents (natural language generation - NLG).

Further processing of extracted or generated data can be applied to build more comprehensive solutions that cover broader operational processes. For example, a company can use NLP to extract an order ID from a bill of lading, allowing it to process the shipment by generating a PO and triggering a number of processes, including transportation management systems for booking transport and then handling invoices.

In general, extensive NLP solutions for intelligent document processing (IDP) can assist logistics service providers in a number of back-office processes which include generating documents, sending automatic alerts, performing automated data extraction (e.g., searching for a particular word or a combination of words in the text), correlating events with other information like images or documents, etc.

Also, most companies face high volumes of emails or support communication daily, including various requests, feedback, opinions, etc., that are a valuable source of data for a business. Traditionally, manual replies and processing such data was a time-consuming task requiring effort, expertise, and organizational resources.

Introducing NLP solutions in a messaging system allows an organization to extract information from unstructured text automatically. It can enhance customer service by resolving requests faster, providing more accurate responses based on knowledge about an issue or a request, etc.

NLP systems can also be applied to automate many functions that are not related directly to business but may affect a company's operational efficiency and customer relations management (CRM). For example, it is possible to integrate automatic sentiment analysis into automated answering systems built on top of a chatbot platform.

Automating Routine Tasks - AI-powered Robotic Process Automation

Robotic process automation (RPA) is a software application that can automatically perform several routine, rules-based tasks a user or a group of users in a company were previously performing manually.

RPA can be used to automate manual and semi-automated business processes that require some level of human interaction, such as finance and accounting operations, data entry, document processing, scheduling operations, etc. The technology called cognitive automation enables an organization to utilize the existing resources more efficiently by freeing employees from time-consuming and tedious work so they can focus on higher value-added activities instead.

For example, an individual working with financial reporting can automate a lot of their mundane work like data entry by using RPA solutions to develop a virtual workforce that will natively work within a company's IT infrastructure. RPA solutions also save a lot of effort and money (because you don't need employees to spend time on repetitive tasks) and speed up business processes while maintaining accuracy and security.

Benefits of AI in Logistics

AI in logistics and supply chains provides a range of benefits, including:

- optimized routes that result in lower fuel consumption and timely deliveries

- lower cost of transportation due to more efficient use of a fleet and space allocation

- increased revenue thanks to higher customer satisfaction through a better service

- fewer errors in a product delivery due to a more advanced data analysis

- lower accidents rates and downtime thanks to proactive parts/machinery servicing

- optimized inventory management due to a more precise forecasting

- higher income thanks to dynamic freight pricing

- increased security of a supply chain with a real-time monitoring

- reduced needs for the human workforce, especially for repetitive tasks and those where autonomous vehicles and machines come in place

- enabled a faster reaction to changing market conditions and a growing number of online customers

How Can Nexocode Experts Help?

nexocode is a leading provider of software solutions for the logistics industry with a portfolio including artificial intelligence-powered fleet management software, intelligent route optimization solutions, dynamic pricing models, +real-time monitoring systems for transportation providers, and other cutting-edge technologies explicitly designed for this sector. nexocode's AI logistics solutions for this industry were developed by a team of experienced and highly-skilled software developers with a deep understanding of the challenges faced by modern supply chain managers.

Wojciech Gębiś

Project Lead & DevOps Engineer

Dorota Owczarek

Design Thinking Facilitator & Product Lead

Oleksandr Zakharchuk

Machine Learning Expert & Advisor

What Nexocode Can Offer as a Boutique AI Development Company?

Bring AI solutions to life. Nexocode team serves clients at every level of AI maturity. Nexocode's offering covers end-to-end artificial intelligence services from AI strategy, advisory, and consulting to implementation and ongoing production support.

AI Design Sprint

Identify AI opportunities and use them to build resilience and business results. We organize AI Design Sprint workshops where you can unleash the artificial intelligence potential and create new value for your business. We will show you how to benefit from artificial intelligence by focusing on people. AI Design Sprint is a low-investment kickstart that will uncover solutions to increase revenues and profits, improve user experience, and much more in just two days.

Proof of Concept Development

Move from the AI Design Sprint towards your first deployment. Nexocode will develop a competitive AI-based solution that solves your company's problem, covers your business needs, and collects and analyzes feedback from testers. Proof of Concept guarantees a much smaller risk of failure, as it only takes a couple of weeks to develop. Still, you can quickly observe what AI brings and decide whether the achieved results look promising enough to follow up with further investment so that you can define your next key goal.

Data Quality Audit

Data represents a new frontier for competitive differentiation. Nexocode offers professional data analysis for your model proposal. We will suggest a data collection strategy to make your model more accurate and provide value to your company. With your data house in order and a transparent process for data management, you will be able to shape your data into an actual business asset.

Building Data Systems

Unlock the value of data with a clear data strategy, process, and technology that supports it. Nexocode will keep you in applying professional MLOps handling Big Data. Practices we use will help guarantee that you can reliably build and operate your artificial intelligence solution at scale. We help our clients to improve their competitiveness by digitizing operations with data-driven insights from deep learning algorithms, which are capable of analyzing huge volumes of unstructured data at record speed.

AI Consulting

With vast expertise in implementing AI systems at scale, the team at nexocode reviews your problem and provides consultations on approaching further steps to complete your business goal and making an impact. We will help you grow beyond the proof of concept stage and implement AI at scale.

AI Consulting

With vast expertise in implementing AI solutions, the team at nexocode reviews your problem and provides consultations on approaching further steps to complete your business goal and making an impact. We will help you grow beyond the proof of concept stage and implement AI at scale.

A development process that brings AI results in weeks, not years

Kickoff

Briefing

2 hours

Explain your business and share your pain points to gain insights into AI capabilities and an approach designed by our nexocode experts.

AI Design

Sprint

2 days

Identify a high-impact business problem and collaborate with nexocode experts to propose an AI solution.

Proof of AI

Development

4 – 12 weeks

Rapidly build an AI model that solves your problem and subsequently test machine learning algorithms on your datasets.

AI Application Deployment

in Production

3 – 9 months

Build automated pipelines, scale, and deploy your artificial intelligence app into production. Adjust algorithms to meet your desired benchmarks.